|

|

Product Information

POWER PURGE is a liquid purging agent designed to quickly and efficiently remove residues from screws, barrels, nozzles, and hot runners in injection molding machines.

POWER PURGE is easy to use and very effective in changing colors and resins because it is a single type of product and is applied to all kinds of thermoplastic materials.

Continuous use of this product can save system maintenance costs.

Property

- Appearance

- Property

Data

-

Specific Gravity

-

1.10 ~ 1.30

-

ASTM D5530-94

-

pH

-

8~10

-

ASTM B527-93

-

FDA No.

-

All substances constituting POWER PURGE are FDA-approved indirect food contact materials.

Strengths

- Reduce cleaning time and costs significantly.

- Clean injection/extrusion systems, blows, and hot runners.

- Easy-to-use liquid purge compounds that are added to existing purge materials.

- A single type of product that can be applied to all kinds of thermoplastic materials

(135~350 degrees Celsius).

- Cost-effective and easy to change colors, replace materials, and reduce dark spots.

- Simple to use and reduces system downtime by 30% or more.

- Clean hot runners when changing colors.

- The periodic use of Power Purge and preventive purging when turning the system on or

off will reduce defect rates.

- Small packaging (20g) ensures convenient use.

Resins

All types of thermoplastic materials including PE , PP , ABS, PS , SAN, and EVA

Shelf life

24 months from the manufacture date (unopened)

Storage

Dry and cool places at or below 25กษ

Packaging

240g box (individually packaged: 20g) and 1 kg boxes (individually packaged: 20g)

How to Use Purge for Injection Molding

- Color change procedure (refer to the injection dosage by machine size attached for the use of Power

Purge)

- Barrels, screws, and nozzles (135กษ ~ 350กษ)

- Shake Power Purge before use

- 1) Maintain the mechanical conditions (screw speed, temperature) used in the final production.

- 2) Empty the existing barrel and hopper cleanly.

- 3) Put the Blank resin that is scheduled to be worked first and immediately put the power purge pack into the hopper according to the table below.

(If the purging resin material to be worked is 1 kg or more, it is effective to inject layers in units of 1 kg during the above 3 and 4 operations.)

- 4) Check the machine to see if there are any contaminated parts. In case such parts are found, repeat stages 2 and 4.

-

5) Start new production.

- Hot runner*

- When purging cylinders, screws, and nozzles, raise the temperature of the hot runner to the maximum allowable limit (30~40 degrees Celsius) for the resin in use to improve flow

- Connect the mold to the nozzle and execute stages 3 and 5

- Purge with the mold open.

- **Note: The barrel should be filled with the resin throughout the entire process.

Dosage for injection molding

Temperature: 135กษ ~ 350กษ

| Injection molding machine |

Resin |

Power purge Dosage |

| 50 ton |

0.30 KG |

6 ml |

| 100 ton |

0.50 KG |

10 ml |

| 200 ton |

1.00 KG |

20 ml(1 pack) |

| 400 ton |

2.00 KG |

40 ml(2 pack) |

| 800 ton |

4.00 KG |

80 ml(4 pack) |

| 1000 ton |

5.00 KG |

100 ml(5 pack) |

| 2000 ton |

10.0 KG |

200 ml(10 pack) |

Extruder Purging

- Color change procedure (refer to the injection dosage by machine size attached for the use of Power

Purge)

- Barrels, screws, and extrusion head (135กษ ~ 350กษ)

- Shake Power Purge before use

- 1) Raise the temperature of the screw and the extrusion head to the maximum allowable limit

(30~40 degrees Celsius) for the resin in use.

- 2) Empty the existing barrel and hopper cleanly.

- 3) Inject the blank resin first before putting the power purge pack in the hopper in accordance with the table below or mixing it with the resin and putting it in the hopper.

(If purging materials weigh 1kg or more, they should be injected layer by layer, 1kg at a time to improve

effectiveness.)

- 4) Pour the resin for the next process in the hopper before the barrel is emptied (without power purge) and increase the speed of the screw to the maximum allowable limit.

- 5) Return the temperature to the normal temperature after the above operation.

(Repeat steps 3 and 4 until the system is clean. (repeat twice to three times))

-

6) Start new production.

- ** Note: The barrel should be filled with the resin throughout the entire process.

Dosage for Extruder

Temperature: 135กษ ~ 350กษ

| Single screw (L/D 30) |

Twin screw (L/D 40) |

Screw diameter

(mm) |

Resin

(kg) |

Power purge

Dosage |

Screw diameter

(mm) |

Resin

(kg) |

Power purge

Dosage |

| 40 |

1 |

20 ml |

30 |

1 |

20 ml |

| 50 |

1.5 |

30 ml |

40 |

2 |

40 ml |

| 60 |

3 |

60 ml |

50 |

4 |

80 ml |

| 70 |

3 |

100 ml |

60 |

7 |

140 ml |

| 80 |

7 |

140 ml |

70 |

12 |

240 ml |

| 90 |

10 |

240 ml |

80 |

20 |

400 ml |

| 100 |

12 |

240 ml |

90 |

30 |

600 ml |

| 120 |

20 |

400 ml |

100 |

36 |

720 ml |

| 150 |

40 |

800 ml |

120 |

50 |

1000 ml |

| 200 |

80 |

800 ml |

130 |

76 |

1520 ml |

Purging for EXTRUSION BLOW MOLDING

- Color change procedure (refer to the injection dosage by machine size attached for the use of Power

Purge)

- Barrels, screws, and extrusion head (135กษ ~ 350กษ)

- Shake Power Purge before use

- 1) Raise the temperature of the screw and the extrusion head to the maximum allowable limit (30~40

degrees Celsius) for the resin in use.

- 2) Empty the existing barrel and hopper cleanly.

- 3)nject the blank resin first before putting the power purge pack in the hopper in accordance with the table below or mixing it with the resin and putting it in the hopper.

(If purging materials weigh 1kg or more, they should be injected layer by layer, 1kg at a time to improve

effectiveness.)

- 4) Pour the resin for the next process in the hopper before the barrel is emptied and raise the speed of the

screw to the maximum allowable limit.

- 5) Return the temperature to the normal temperature after the above operation.

(Repeat steps 3 and 4 until the system is clean. (repeat twice to three times))

-

6) Start new production.

- ** Note: The barrel should be filled with the resin throughout the entire process.

Dosage for Extrusion Blow Molding

Temperature: 135กษ ~ 350กษ

| Single screw (L/D 30) |

Twin screw (L/D 40) |

Screw diameter

(mm) |

Resin

(kg) |

Power purge

Dosage |

Screw diameter

(mm) |

Resin

(kg) |

Power purge

Dosage |

| 40 |

1 |

20 ml |

30 |

1 |

20 ml |

| 50 |

1.5 |

30 ml |

40 |

2 |

40 ml |

| 60 |

3 |

60 ml |

50 |

4 |

80 ml |

| 70 |

3 |

100 ml |

60 |

7 |

140 ml |

| 80 |

7 |

140 ml |

70 |

12 |

240 ml |

| 90 |

10 |

240 ml |

80 |

20 |

400 ml |

| 100 |

12 |

240 ml |

90 |

30 |

600 ml |

| 120 |

20 |

400 ml |

100 |

36 |

720 ml |

| 150 |

40 |

800 ml |

120 |

50 |

1000 ml |

| 200 |

80 |

800 ml |

130 |

76 |

1520 ml |

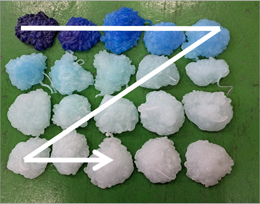

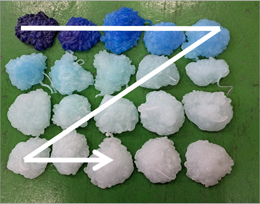

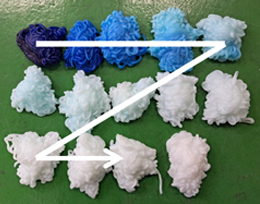

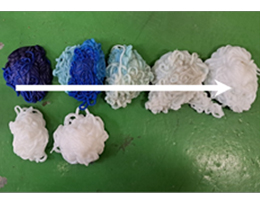

POWER PURGE Use: Sample 1

PP BLANK

After using other resins

PP POWER PURGE

After using POWER PURGE

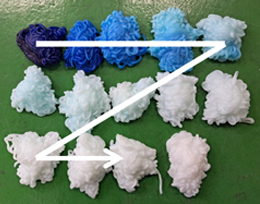

POWER PURGE Use: Sample 2

PE BLANK

After using other resins

PE POWER PURGE

After using POWER PURGE

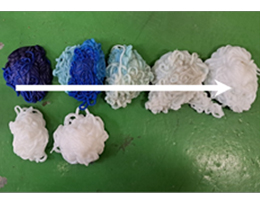

POWER PURGE Use: Sample 3

ABS BLANK

After using other resins

ABS POWER PURGE

After using POWER PURGE

|